5-AXIS

HONEYCOMB

PROCESSING CELL

ERGONOMIC CNC ROUTER SPECIFICALLY FOR HONEYCOMB MATERIAL

SINGLE SPINDLE 3-AXIS

SINGLE SPINDLE 5-AXIS

TWIN SPINDLE 3-AXIS

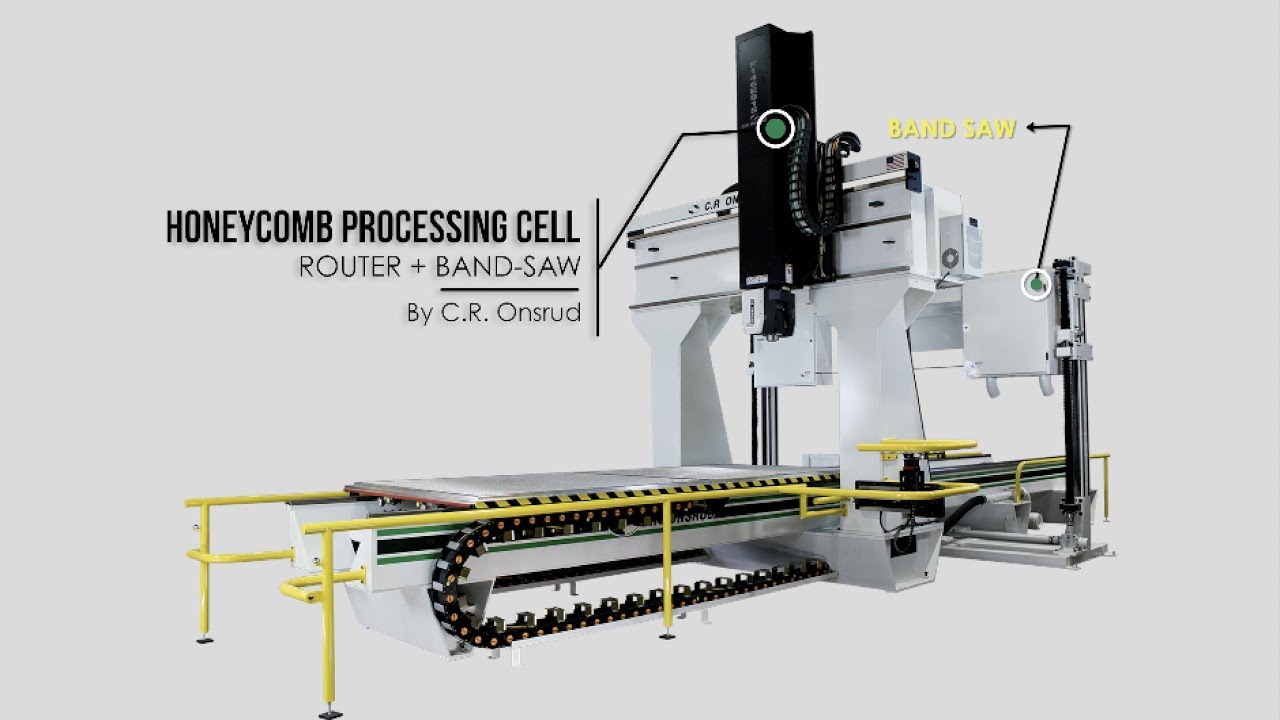

Honeycomb Processing Cell

SINGLE SPINDLE 5-AXIS

S-SERIES

SINGLE SPINDLE 3-Axis

S-SERIES

Twin Spindle 3-Axis

S-SERIES

Single Spindle 5-Axis

S-SERIES

AUTOMATION

ES-SERIES

SINGLE SPINDLE 5-AXIS

ES-SERIES

Honeycomb Processing Cell

Table Sizes

Ergonomic, Exceptional Performance

for processing honeycomb material

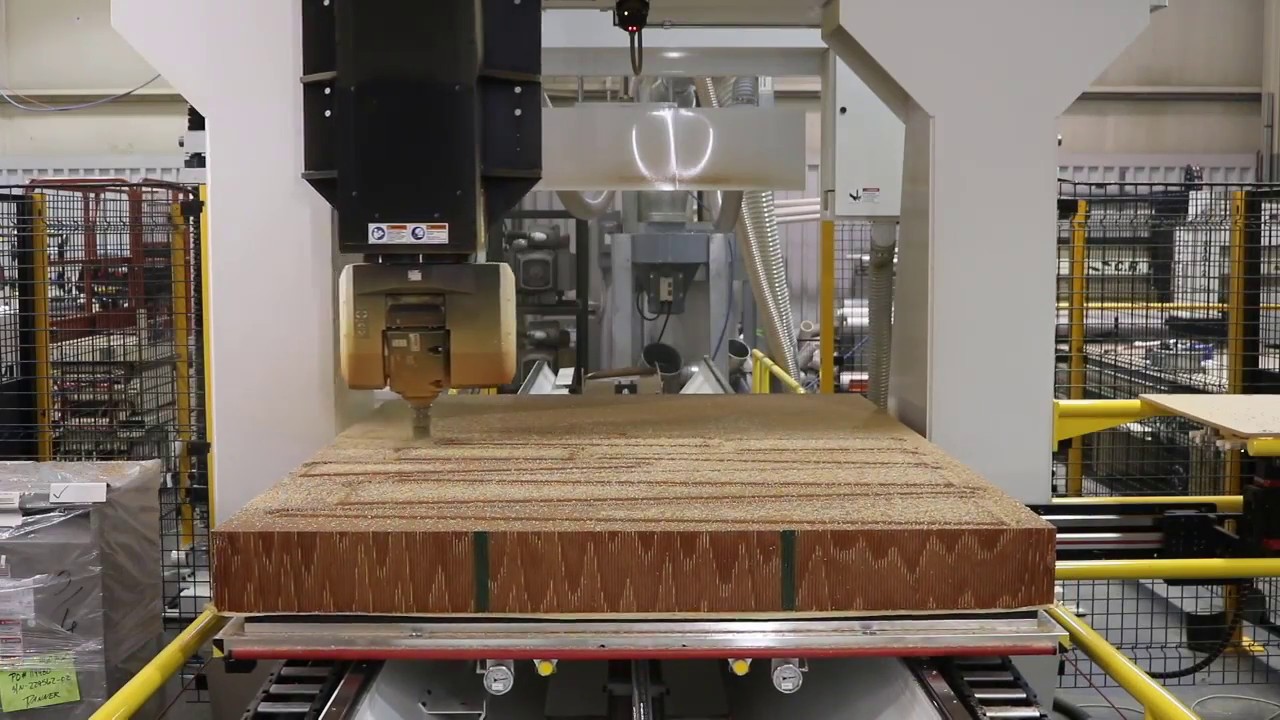

The C.R. Onsrud Honeycomb Processing Cell is engineered to provide the fastest, most efficient solution to companies competing within the honeycomb manufacturing industry. By integrating a C.R. Onsrud 5-Axis ES-Series CNC Router with an industrial-grade high-precision Bandsaw, our engineers were able to create a manufacturing cell that provides seamless integration between cutting and machining operations. Minimize your downtime, increase your throughput, and reduce your reliance on skilled operators.

Integrate C.R. Onsrud’s automated material-handling systems that fit the flow of your production. With customized linear and cell-based solutions, you get as much or as little automation as you need, from simple loading/offloading with or without pre-labeling to fully automated material storage and retrieval systems with integrated routers and saws. See also Automation for more information.

Standard:

15HP

24,000

12

28"

Upgrades:

24, 33, 75HP

2nd

24

28, 40, 53"

| MODEL | F62S | F122S | F146S |

|---|---|---|---|

| 28" Z | |||

| Table Size: X | 60 | 120 | 144 |

| Table Size: Y | 60 | 60 | 60 |

| Machine Size: L | 147 | 260 | 310 |

| Machine Size: W | 163 | 153 | 163 |

| Machine Size: H | 140 | 143 | 153 |

| Vacuum Zones (standard #) | 1 | 2 | 3 |

| 40" Z | |||

| Table Size: X | 120 | ||

| Table Size: Y | 60 | ||

| Machine Size: L | 260 | ||

| Machine Size: W | 153 | ||

| Machine Size: H | 162 | ||

| Vacuum Zones (standard #) | 2 |

| MODEL | F62S | F122S | F146S |

|---|---|---|---|

| 28" Z | |||

| Table Size: X | 1524 | 3048 | 3658 |

| Table Size: Y | 1524 | 1524 | 1524 |

| Machine Size: L | 3734 | 6604 | 7874 |

| Machine Size: W | 4141 | 3887 | 4141 |

| Machine Size: H | 3556 | 3633 | 3887 |

| Vacuum Zones (standard #) | 1 | 2 | 3 |

| 40" Z | |||

| Table Size: X | 3048 | ||

| Table Size: Y | 1524 | ||

| Machine Size: L | 6604 | ||

| Machine Size: W | 3887 | ||

| Machine Size: H | 4115 | ||

| Vacuum Zones (standard #) | 2 |

ACCESSORIES

Customize the Honeycomb Processing Cell with accessories. Here you’ll find ways to increase your productivity. Select your tool lubrication, eliminate measuring errors with automatic tool measurement systems, and more.

C-AXIS

With a C-Axis (aka 4th axis), you can machine at an angle, including on the sides of your material, to create complex contours (such as helixes), otherwise not possible with a 3-axis machine. This comes standard on a 5-axis machine.

CONTINUOUS C-AXIS

With continuous C-Axis, a 5-axis machine gets unrestricted rotational movement of the C-axis. Without this option, a traditional 5-axis spindle has to unwind itself after a set amount of rotation.

AIR BLAST

Bursts of air keep tools cool and remove debris and chips from the cut without the need for coolant.

COLD AIR BLAST

Cold air blast removes chips and cools the tool when cutting metals or various abrasive materials.

ATLM SYSTEM (METROL)

Precisely measures the length of your tool and automatically feeds that value into your CNC machine controls.

ATLM SYSTEM: TS27R (RENISHAW)

Precisely measures the length and diameter of your tool and automatically feeds that value into your CNC machine controls. It also detects if a tool is broken.

ATLM: NC4 (RENISHAW)

Precisely measures the length and diameter of your tool, without contact, and automatically feeds that value into your CNC machine controls. It also detects if a tool is broken. NC4 is application dependent; table constraints may apply.

AUTOMATIC GREASE LUBRICATION

Automatically greases your tools, bearings, and ball screws at regular intervals.

GREASE DRIP PANS

Drip pans (a.k.a. trays) catch excess lubrication that might otherwise cause contamination or other hazards.

LINEAR ENCODER (SCALES)

With noncontact sensing, linear encoders (scales) measure and monitor linear movement, position, and speed and provide that feedback to your CNC machine.

VOLUMETRIC LASER COMPENSATION

With volumetric laser compensation, machining tools are automatically calibrated and the machine makes any necessary adjustments.

Note: Depending on your machine, C.R. Onsrud sends out a third-party A2LA-accredited company to your facility to perform volumetric compensation.

DUST / CHIP MANAGEMENT

Dust management systems connected to appropriate dust collection systems capture chips, dust, and other airborne particles that would otherwise be harmful to humans and the machining environment. We offer dust management systems that are geared toward the materials you’re machining and your production environment.

SERVO HOOD™

With CR Onsrud’s innovated servo-positioned dust hood, we have improved upon the standard 2-position dust hood and given the CNC the ability to automatically adjusts the dust hood’s height offset based on tool length, relative to the workpiece. This helps customers who machine with a variety of tool length get superior dust collection regardless of the tool length.

DUST STANCHION KIT

Designed for low ceilings and shop floors with layout constraints, a dust collection stanchion kit transitions dust to your collector from either side of the machine.

OVERHEAD OFFLOAD DUST HOOD

Targeted to the machining area, a dust hood suctions away dust and debris that can impact your health as well as the performance of your CNC machine.

AIR KNIFE

Engineered especially for fine or coarse chips (e.g., hard composites, fiber cement, metal, etc.), programmable air knives clear harmful debris from your linear guides.

REAR ENCLOSURE

Partial standalone enclosures provide additional safety when the back of a machine is not against a wall.

MANUAL SLIDING DOORS

These doors are manually controlled by you for access to the machine’s enclosure. For safety purposes, the doors should be closed when the machine is in operation.

AUTOMATIC SLIDING DOORS

These doors are activated and controlled by PMC servo motors. For safety purposes, the machine is placed in a feed hold state if the doors are not properly closed.

ENCLOSURE DUST COLLECTION PORTS

Dust collection ports are integrated with your vacuum system to move dust and debris away from the work area.

LIDAR CURTAINS

The Onsrud lidar safety curtain sets an invisible barrier that triggers your machine’s E-Stop when crossed.

SAFETY MATS

Safety mats sense the pressure of an operator or object on them, alerting the machine to turn off.

AUTOMATION

Automated material-handling systems fit the flow of your production to make manufacturing processes more efficient and safe.

STATIC PRE-STAGE TABLE WITH OR WITHOUT PUSHER

Automatically reloads the scissor lift with another bunk of material prior to the first bunk running out. Since your material load is always stocked, you never have to synchronize your forklift timing or stop production.

PUSHER SWEEPER

The pusher automatically clears the machining area by moving parts to an offload table while the sweeper sucks up any additional dust and debris.

STATIC OUTFEED

A static outfeed table provides a work area for sorting and stacking parts without interrupting the machining operations.

PRE-LABELING SYSTEM

Pre- or post-affix removable labels to parts for tracking, identification, or to provide descriptive details. (Most common for cabinets and sheet goods).

PART MARKING - INK

Applies marks (e.g., alpha-numeric), without contact, for part tracking. Marks can be permanent or removed based on how porous the material is.

PART MARKING - PAINT

Applies one or multiple colored paint for layout lines and shapes/symbols needed downstream (e.g., hot/cold water lines, nail locations, wiring, etc.) (Commonly used in the prefab home industry).

STANDALONE LABEL PRINTER

This auxiliary equipment can create and affix labels to parts for tracking and identifying parts for use in downstream operations or at the job site.

BARCODE SCANNER

Scan a barcode (machine-readable data) from a document and the machine automatically retrieves the specified program, tooling list, and set-up directions for that job.

ROBOTICS INTEGRATION

Devices are strategically incorporated into your production to automatically perform repetitive tasks, so you and your team can focus on projects that grow your business.

TOOLING

Onsrud Tooling is a direct and easy way to buy high-quality cutting tools at great prices for your Onsrud machine. Choose from:

Drill Blocks support the simultaneous machining of a set number of holes, evenly spaced with the same or varying diameters. These are not available on a 5-axis machine, but if you’re interested in this capability, see our S-Series 3-Axis machine.

Depending on your specific application, the Honeycomb Processing Cell supports 1000’s of specialty tools to perform specialized functions for unique projects. Not all aggregates work with every machine configuration. We recommend discussing your specific application requirements with our team.

Saw Blades attach to a CNC machine to create intricate notches, miter cuts, and straight cuts on up to 5 sides of your material on a 5-axis machine. The saw can also be used as a cutoff tool.

Not sure what you need? We’ve got you covered, our knowledgeable staff is on hand to help with your tooling needs.

DRILL BLOCKS

(not available on 5-axis machines)

AGGREGATE RING

At a fixed position, an aggregate ring always maintains your tools centered and at a consistent depth into the material you’re cutting.

90° HEAD

A 90° head gives you the capability to perform lateral machining operations on a 3-axis machine.

DUO 90° HEAD

A Duo 90° head gives you the capability to perform lateral machining operations using different tools in opposite directions on a 3-axis machine.

QUAD 90° HEAD

With a Quad 90° head, you’ll easily add lateral machining operations to your 3-axis machine using four tools in each direction.

ADJUSTABLE ANGLE

An adjustable angle head allows you to set the angle at which you want to cut, for up to 5-sided machining on a 3-axis machine.

FLEX ANGLE

With a flex angle head, you can perform horizontal and angular machining operations on a 3-axis machine without having to reposition your workpiece.

MOULDER HEAD

Mill, plane, carve, and bevel, symmetrical and asymmetrical shapes on a 3-axis machine, with the addition of a moulder head aggregate.

OSCILLATING KNIFE

Cut out sharp corners and radii from flexible materials, such as packaging foam, tool foam, plastic, or cardboard with an oscillating knife aggregate.

SMALL DIAMETER SAW BLADE

(up to 6″)

The spindle automatically picks up and returns small diameter saw blades (up to 6″) from the station that is mounted on the machine’s bridge or column.

Note: (Requires a 5-axis machine unless an aggregate is utilized)

DEDICATED AGGREGATE STATION

With a dedicated aggregate station, you can automatically store and retrieve specialty tools (such as saw blades) that are too large or heavy to fit in a standard automatic tool changer.

WORK HOLDING & POSITIONING

These devices accurately locate your workpiece in orientation to the table and the tooling. To properly secure your workpieces, it is important to have the correct work-holding device for the material you are cutting. Proper work holding and material positioning ensure precise and efficient machining.

CUSTOM VACUUM ZONES

With custom vacuum zones, you tailor the size and location of vacuum areas for part-holding and can shut off sections of the table to concentrate vacuum to specific zones.

ONSRUD MATRIX GRID TABLE

The Onsrud grid table provides a grid pattern for multiple part-holding options, such as gasketing, vacuum pods, clamps, etc. and is compatible with most third-party products.

CUSTOM / MECHANICAL FIXTURING TABLE

Custom fixturing is adapted to hold irregularly shaped parts or panels that cannot be held by traditional methods.

T-SLOT

The channels of T-Slot tables are used for linear positioning of clamps and vices across the surface of the machine’s table.

LATHE (ROTARY)

With a rotary axis lathe or chuck, your machine operates as a turning center with live tuning. It rotates bar stock and long and skinny components to create chair legs, columns, etc.

REFERENCE (POP-UP) PINS

Reference pins are for quick, reliable, and repeatable placement of your workpieces on your CNC machine.

PROBING

(RENISHAW PROBE)

A part-probing system adjusts the origin of your part prior to machining, performs in-process QC for tight tolerance applications, and performs post-machining QC to approve or reject a part before it is taken out of its work holding.

LASER PATTERN PROJECTION SYSTEM

Without touching the material, a Laser Pattern Projection Alignment System provides true to scale patterns of one or several aligned or nested objects, transferred from CAD software onto the CNC table.

Note: This option is common for high-mix shops and when using vacuum pods.

VISION RECOGNITION (FIDUCIAL)

A fiducial vision recognition system scans for reference points to identify a sheet’s position. The program and tool paths automatically adjust to the position.

Note: This option is common in the signmaking industry where sheets are otherwise difficult to align perfectly.

BUTTONS

EXTRUSION SPECIFIC

COMMON APPLICATIONS

Here are some of the industries that have often purchased our Honeycomb Processing Cell. If your industry is not listed, the Honeycomb Processing Cell may still be the right choice for your shop as it depends on your specific application. Please contact us if you would like help determining if the Honeycomb Processing Cell is the right machine for you.

AEROSPACE

AEROSPACE

From engine components to tail boom structures, landing gear, fuselages, and much more, produce reliably fitting components, quickly, and to your exact specifications.

AUTOMOTIVE

AUTOMOTIVE

Expand, modernize, or customize your existing automotive product line or launch new products by automating manual processes and increasing your shop’s capacity.

COMPOSITES

COMPOSITES

Machining composites can be tough — Onsrud machinery is engineered to handle harsh, dirty machining environments and the unique characteristics of composites.

MILITARY AND DEFENSE

MILITARY AND DEFENSE

Gain fast, consistently accurate results that comply with the tolerances set by government regulations and that meet, if not exceed, your high standards.

PATTERNS AND MOLDS

PATTERNS AND MOLDS

Onsrud CNC machinery performs quick and accurate cuts, angle cuts, undercuts, and finishes, eliminating the need for multi-part molds and handwork.

Aerospace

AUTOMOTIVE

Composites

Military & Defense

Patterns & Mold

AEROSPACE

From engine components to tail boom structures, landing gear, fuselages, and much more, produce reliably fitting components, quickly, and to your exact specifications.

AUTOMOTIVE

Expand, modernize, or customize your existing automotive product line by automating manual processes and increasing your shop’s capacity.

COMPOSITES

Machining composites can be tough — Onsrud makes it easy with machinery engineered to handle harsh, dirty machining environments and the unique characteristics of composites.

MILITARY & DEFENSE

Gain fast, consistently accurate results that comply with the tolerances set by government regulations and that meet, if not exceed, your high standards.

PATTERNS AND MOLDS

Onsrud CNC machinery performs quick and accurate cuts, angle cuts, undercuts, and finishes, eliminating the need for multi-part molds and handwork.

Machine Demo